HEP Elektra d.o.o. is the national distributor of electrical energy for the Republic of Croatia. Within the supply network, there are numerous transformer stations that are remotely connected to central units, and the presence of personnel is only required in cases of local supervision, interventions, repairs, and similar situations. In the event of emergencies in the water supply infrastructure, the response time was quite long, leading to operational problems and financial losses. IKOM d.d. installed Data loggers at 25 locations in the city of Zagreb for the client, enabling alarm notifications and continuous insight into daily and nightly flows and the consumption of measuring points.

Challenges:

- Operational costs: HEP Elektra d.o.o. faced high operational costs associated with leaks and pipe bursts at transformer station locations where personnel are rarely present.

- Measurement accuracy: The goal was to provide the client with accurate reading data, minute-by-minute flow insights, nighttime flows, and alarms.

- Response time: Since there are no employees at the locations, the response time from the beginning of the accident was longer, sometimes exceeding a month. It was essential to provide the client with an instant solution so that they could receive notification immediately in the event of an unforeseen situation.

Project goals:

HEP Elektra engaged IKOM d.d. with the aim of addressing the aforementioned challenges through the modernization of the measuring system at remote measurement points. The key project goals included:

- Reducing operational management costs by efficiently monitoring and maintaining infrastructure.

- Improving the accuracy of water consumption measurements through the implementation of modern measuring devices and technologies.

- Enabling rapid identification and resolution of issues with measurement point infrastructure through daily monitoring and data analysis.

Solutions:

IKOM approached the project with the aim of addressing the key challenges faced by the client through the implementation of a modern monitoring system for measurement points using Data loggers:

1. Sofrel Data loggers:

The installation of Data loggers from the partner company Lacroix Sofrel was proposed. These devices record water flows and consumption at each measurement point every minute, and then send all data once or multiple times daily to a centralized web system.

2. Communication Infrastructure:

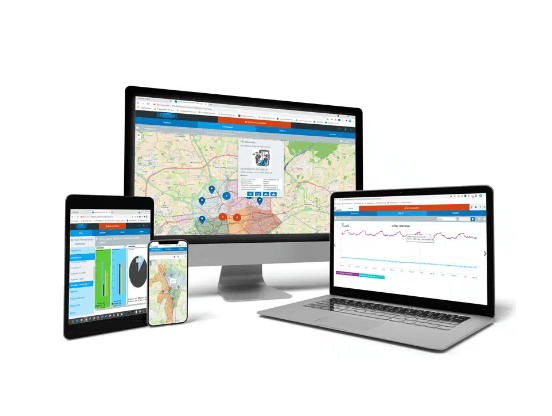

Data loggers are equipped with GPRS/LTE data cards through which the device sends data daily to the centralized SCADA web system. Access credentials were provided to the client so they could monitor the desired measurement point at any time.

3. Education:

To ensure successful implementation and optimal utilization of the new measurement system, comprehensive training was provided to the client's technical staff on the use of the software platform for data analysis.

Implementation:

The project implementation proceeded with minimal involvement of the client's technical staff and was covered in the following phases:

Phase 1 - Installation of Data loggers on existing water meters in the system

- An assessment of the existing infrastructure was conducted, concluding that the existing IKOM water meters, with minimal upgrades, were suitable for the installation of Data loggers.

Phase 2 - Establishment of communication infrastructure:

- GPRS SIM cards from the local A1 operator were inserted into the devices to enable wireless data transmission from the Data loggers to the SCADA system.

- Communication links were tested to ensure the reliability and security of data transmission.

Phase 3 - Introduction of software platform:

- The Sofrel PC Win2 server platform was implemented for the analysis and management of collected data.

- Technical staff were trained in the use of the new platform, including how to analyze flow and water consumption data, as well as identify and resolve issues at the measurement point.

Results:

The implementation of this smart water metering system has brought significant benefits to HEP Elektra d.o.o., including:

- Reduction of operational costs through efficient maintenance and management of infrastructure.

- Insight into consumption - The implementation of Data loggers allows administrators to see water consumption at each facility at any given time.

- Rapid identification and resolution of issues - Monitoring enabled quick identification and resolution of problems at measurement points, thereby reducing costs due to pipe bursts and leaks by 95%.